Solar technology for wastewater treatment in Butha Buthe, Lesotho

Submitted by Ivan YaholnitskyPublished 4 years, 3 months ago

During the second quarter of this year, Bethal Business and Community Development Centre (BBCDC) constructed a wastewater treatment system/living machine at at Queen Mamohato Children’s Village in Butha Buthe that applies simple yet powerful solar thermal technology to significantly enhance process, economy, and environment. This is the third such structure developed by BBCDC in Lesotho.

The problem being addressed was that of an original septic system built without any release or cycling capacity. This meant that the entire volume of wastewater had to be removed regularly using vacuum trucks and was a crippling expense for the centre. More generally, septic systems and pit latrines suffer a broad array of design defects.

Water has the unusual property of being both a perfect absorber and a perfect reflector. What this means is that in winter or morning and evening, facultative ponds used for water treatment receive little light or energy. In addition, septic systems operate in the ground where there is no light, active circulation, oxygen, green plants, and at a reduced temperature. Bio-reaction is inhibited and slow. Pit latrines on the other hand lock waste for long periods of time, resulting in severe localized pollution.

During the 1970s, environmental engineers John and Nancy Todd generated the term and concept of “living machines” for wastewater treatment. Their substantial and powerful innovation was to introduce light, aeration, circulation, higher temperatures, and biodiversity to the architecture of wastewater treatment within greenhouses.

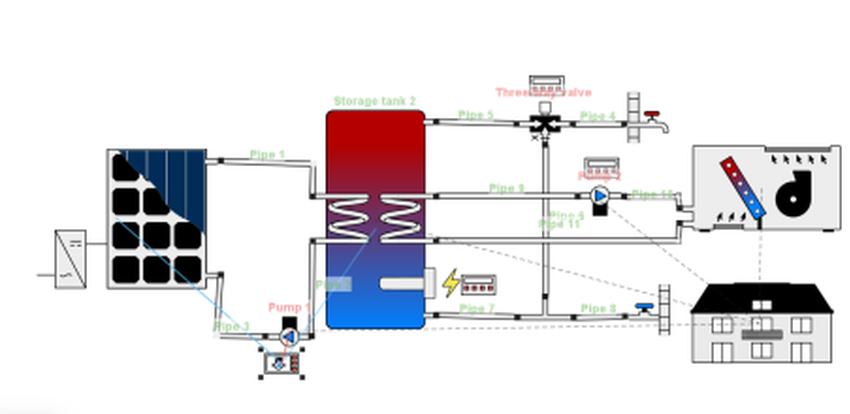

In parallel, the Brace Research Institute at McGill University developed greenhouse technology based on designed geometry for the Canadian winter that was vastly more energy-efficient than simple shell/dome structures. A valid model for efficient wastewater treatment must be premised on natural cycles, which include dispersal, digestion, dilution along with the elimination of pollution and toxicity. Living machines use light, oxygen, water, and higher temperatures to break down solid wastes rapidly and pass nutrients on to point of next use where they will be valuable as in nature. The living machine consists of five separate chambers with a total volume of 60m3. The first two are anaerobic. The first chamber includes a biogas digester - a 1000 liter plastic polypropylene tank inverted. Waste flushes directly into the bottom of the tank. The tank is supported off the bottom of the digester and held in place by the concrete slab cast over this portion of the machine. The greenhouse is 3m x 6m with a 6m x 3.6m solar aperture which admits plenty of light and thermal energy. The back wall of the greenhouse serves to reflect light down into the last three chambers, adding to the direct solar gain.

The centerpiece of the installation is the greenhouse section which includes 3 separate chambers. Each chamber is further divided into two sections by stacks of old tires filled with crushed stone or sand. The sand and crushed stone act as surface media for the growth of bacteria and algae and bio-reaction, mimicking the operation of a reef. Wastewater must plunge when flowing from one chamber to the next, which adds air. A circulation pond pump is installed in the central chamber to circulate water and also includes a simple Venturi which adds more air to the water. The greenhouse ensures the addition of plenty of light to the water and high temperatures. Treated wastewater is pumped from the last chamber to a series of 3 facultative ponds by means of a sump pump with a float valve and is actuated automatically.

Brace greenhouse structures have many applications for space heating, plant propagation, induced ventilation, solariums, and so on. Several years ago, BBCDC was forced to go as far afield as Port Elizabeth in RSA to source the clear polycarbonate. It is now available locally at a reasonable price and has many applications for solar energy gain in the built environment.

Additional synergies include:

- A student from the National University of Lesotho’s MSc in Renewable Energy will carry out a thorough study of the performance of the wastewater system.

- The geometry of the greenhouse complements the lines of Princess Diana Hall and maintains symmetry and visual proportion on campus.

- Excellent experiential learning and authentic education was realized for 15 BBCDC students and an intern from Lerotholi Polytechnic including five women.

BBCDC is the lead partner for SOLTRAIN in Lesotho.